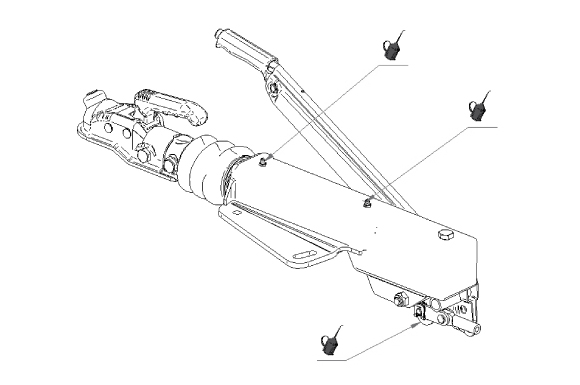

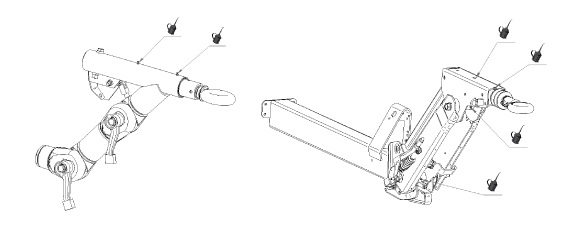

For the maintenance of a Hubière trailer straight drawbar, regularly check the tension of the brake linkage (approximately 5 notches at most to operate the handbrake lever). Your brake control has a shock absorber to ensure gradual braking. This is a wearing part requiring special attention. When it needs to be replaced, you will feel some jerking (the impression of feeling the trailer pushing the vehicle or sudden braking of the trailer). Check the breakage cable designed to trigger the braking system in the event of towing vehicle coupling breakage. This cable corresponds to a special use (hitching ring opening programs according to tension) and can only be replaced by a cable corresponding to the manufacturer requirements.

For the maintenance of a Hubière trailer straight drawbar, regularly check the tension of the brake linkage (approximately 5 notches at most to operate the handbrake lever). Your brake control has a shock absorber to ensure gradual braking. This is a wearing part requiring special attention. When it needs to be replaced, you will feel some jerking (the impression of feeling the trailer pushing the vehicle or sudden braking of the trailer). Check the breakage cable designed to trigger the braking system in the event of towing vehicle coupling breakage. This cable corresponds to a special use (hitching ring opening programs according to tension) and can only be replaced by a cable corresponding to the manufacturer requirements.This type of drawbar requires a regular inspection of the condition of the notched stopping teeth, the threading of the shafts and the keys, designed to lock the drawbar when it is adjusted.

Similarly, check that the parts are free of play and that the drawbar is adjusted according to the indications given in the chapter entitled “use of your trailer”.

For a braked trailer, regularly grease the brake control. Servicing of the height-adjustable drawbar of the remorques Hubière trailer.

Check regularly the tension of the brake linkage (approximately 5 notches maximum to operate the hand operated brake lever). Your brake control has a damper designed to ensure smooth braking. This part wears and requires special attention. When it needs replacing, you will feel perceptible jerking (the impression of the trailer pushing the towing vehicle with the abrupt braking of the trailer). Check the breakage cable which triggers the brake system in the event of the towing vehicle coupling breaking free. This cable corresponds to special purposes (programmed hitching ring opening according to tension) and can only be replaced by a cable corresponding to the manufacturer’s recommendations. NB: The coupling of your towing vehicle must also be inspected regularly (attachments, condition of the fitting). Tow balls are prone to wear and need to be replaced when they are no longer of the right dimension (see your mechanic).

Check regularly the tension of the brake linkage (approximately 5 notches maximum to operate the hand operated brake lever). Your brake control has a damper designed to ensure smooth braking. This part wears and requires special attention. When it needs replacing, you will feel perceptible jerking (the impression of the trailer pushing the towing vehicle with the abrupt braking of the trailer). Check the breakage cable which triggers the brake system in the event of the towing vehicle coupling breaking free. This cable corresponds to special purposes (programmed hitching ring opening according to tension) and can only be replaced by a cable corresponding to the manufacturer’s recommendations. NB: The coupling of your towing vehicle must also be inspected regularly (attachments, condition of the fitting). Tow balls are prone to wear and need to be replaced when they are no longer of the right dimension (see your mechanic).Chassis / Body parts

All these components of the chassis and body all your trailer are entirely hot-dip galvanized. This surface treatment ensures that your trailer is able to resist the long-term effects of a non-hostile environment. In a hostile environment (salt spray), this life may be shorter.

The galvanizing will not stay glossy for a long time; it will eventually tarnish, a visual sign of the completion of the galvanizing process. Galvanizing does not require any specific servicing other than cleaning with fresh water when the condition of the trailer so requires.

All the parts and accessories are bolted together with electro-zinc-plated hardware not requiring any special servicing.

Tyres

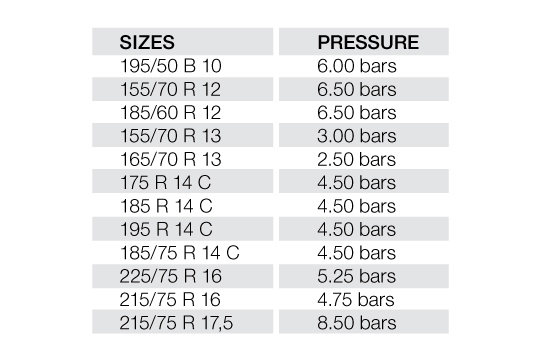

For the safety of the towing vehicle/trailer rig, check the tyre pressures every time you are going to use them.

A label indicating the pressures, given in the following table, is to be affixed to the fender of the trailer and will enable you to carry out this check very easily.

The wheels of your trailer are specific and cannot be replaced by wheels from cars.

Similarly, when you replace the tyres, ensure that the load and speed ratings conform to those of the replaced tyres.

Tyre repairs can be carried out by qualified people and, in all cases, must be done after the removal of the tyre casing.

After the first 1000 km, tighten the wheel nuts and regularly check that they are tight, using a torque wrench and in application of the torque loads.

Lighting

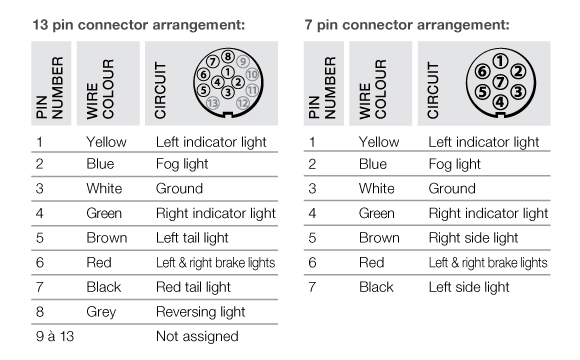

Starting from 29/10/2012, in accordance with the European Directive 2007/46 CE and more particularly with UN regulation 48, trailers must be provided with a 13 pin connection harness instead of a 7 pin unit.

To prepare for this change, Remorques HUBIERE, starting from August 2012, has decided to introduce the new harnesses little by little.

If your vehicle has an electric harness which does not correspond to that of your trailer, a range of accessories is available on sale from our spare parts service: 7/13 pin adapter, 13/7 pin adapter.

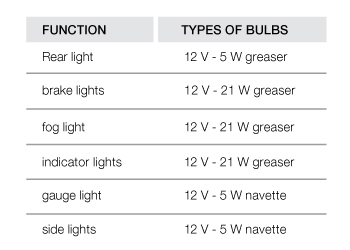

If a bulb blows, replace it by unscrewing the caps over the light, and replacing the bulb by a bulb having the same power rating.

Before using your trailer, check that all the lights operate properly.

Axles

■ the suspension does not require servicing,

■ damping is flexible,

■ the wheels are independent This particularly sensitive part of your suspension must never be modified or repaired without the prior approval of the manufacturer. The components of your axle are type approved; any change without notice of approval will result in the cancelling of the warranty. Each axle has an identification plate swaged into the middle of the axle body and allowing traceability.

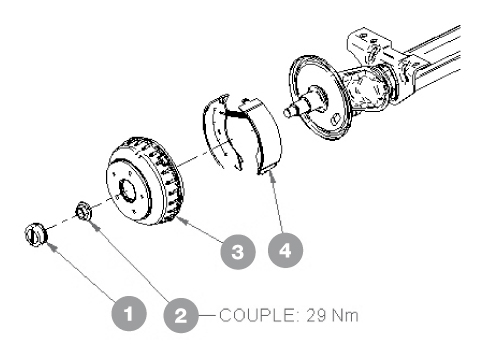

■ taper bearings, in which case greasing is required every 10,000 km or every year :

■ Take the retaining pin out of the castellated nut

■ Tighten the castellated nut until resistance to rotation is felt.

■ Finish off tightening using a torque wrench.

■ Replace the grease, fit the pin and the hub cap.

The bearings can be extracted and reinstalled with a bearing press and it is essential to tighten them to a torque load of 29 Nm.

Brakes

To release the brake, press the button on the lever and lower the lever.

The brake linings need to be checked every 5000 km or at least once every year.

Use original parts exclusively for replacing them.

■ Unscrew the flanged

■ Release the traction spring

■ Clean the inside of the flange and the drum.

■ Fit the new linings in place.

■ Reassemble by working in the opposite order.

The removal of a drum makes it compulsory to replace the hub lock nut.

In all cases, we advise you to refer to a professional to perform these operations.

Aluminium ramps.

To ensure that the ramps adhere, clean the running surface regularly.

Check the condition of the hinges and articulations before use.

In the event of cracks appearing, do not use the ramps and contact your distributor.

Hydraulics

Check the condition of the flexible lines between the pump and the hydraulic actuator(s) of the trailer.

These flexible lines must be in excellent condition without any cracking. After a few years of use, the flexible lines may show this type of defect and will need to be replaced.

If there is an oil leak from the hydraulic system, seal kits are available to correct them.